PET Strapping Recycling Machine Manufacturers in Kenya

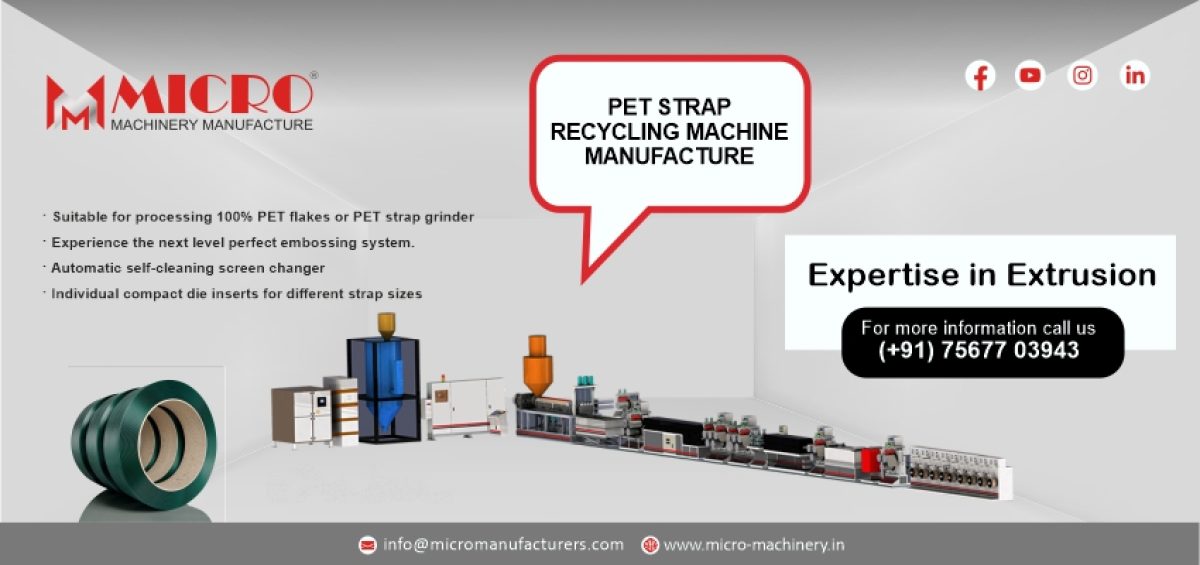

Pet strap extrusion line offered by MICRO is suitable for making straps from 100% PET bottle flakes or 100% recycled PET strap grinder with dedicated parameters and accessories set to suit quality straps.

A PET strap extrusion line machine is a specialized production line used to manufacture PET (Polyethylene Terephthalate) straps. These straps are commonly used in various industries for packaging, bundling, and securing items, such as palletized goods or heavy-duty products.

Key Features of PET Strap Extrusion Lines:

- High Productivity: Capable of producing a large quantity of straps in a short amount of time.

- Adjustable Thickness and Width: The line can be adjusted to produce straps of different thicknesses and widths based on the requirement.

- Energy Efficiency: Modern lines are designed to be energy-efficient, reducing production costs.

- Durability and Strength: PET straps produced using this machinery have high tensile strength, making them ideal for securing heavy loads.

Why Choose PET Straps Over Other Materials?

There are several reasons why PET straps are favored over other traditional materials like steel and polypropylene:

- Lightweight Yet Strong: PET straps are lightweight, making them easier to handle and apply. Despite their lightweight nature, they offer excellent strength and durability.

- Weather-Resistant: PET straps are resistant to UV rays, moisture, and chemicals, making them suitable for outdoor storage and transportation in harsh environments.

- Cost-Effective: Compared to steel straps, PET straps are more cost-effective, offering a durable alternative that is less expensive to produce and handle.

- Eco-Friendly: PET straps are recyclable, offering an environmentally friendly alternative to steel and other non-recyclable materials.